Investment casting, also known as lost wax casting, is one of the oldest and most precise metal casting methods in use today. With its ability to produce complex shapes, smooth surfaces, and tight tolerances, it plays a vital role in industries that demand high performance and quality.

In this comprehensive guide, we break down how investment casting works, what makes it special, and how it compares to other manufacturing techniques.

What Is Investment Casting?

Investment casting is a precision casting process that uses a wax pattern to create a ceramic mold. After the wax is melted out, molten metal is poured into the mold to form the final part. The result? High-detail, near-net-shape metal components that require minimal post-processing.

This method is suitable for small to medium parts and is often used for stainless steel, carbon steel, aluminum, bronze, and even superalloys.

How Does Investment Casting Work?

Here’s a simplified breakdown of the investment casting process:

- Wax Pattern Creation: A wax model is created using an aluminum mold. Multiple wax patterns may be attached to form a casting tree.

- Shell Building: The wax pattern is repeatedly dipped into ceramic slurry and coated with sand. After several layers, a strong ceramic shell forms.

- Dewaxing: The assembly is heated to melt out the wax, leaving a hollow ceramic mold.

- Mold Firing: The mold is fired at high temperature to harden it and remove any residue.

- Metal Pouring: Molten metal is poured into the mold while it’s still hot.

- Cooling and Removal: Once cooled, the ceramic shell is broken away to reveal the cast metal part.

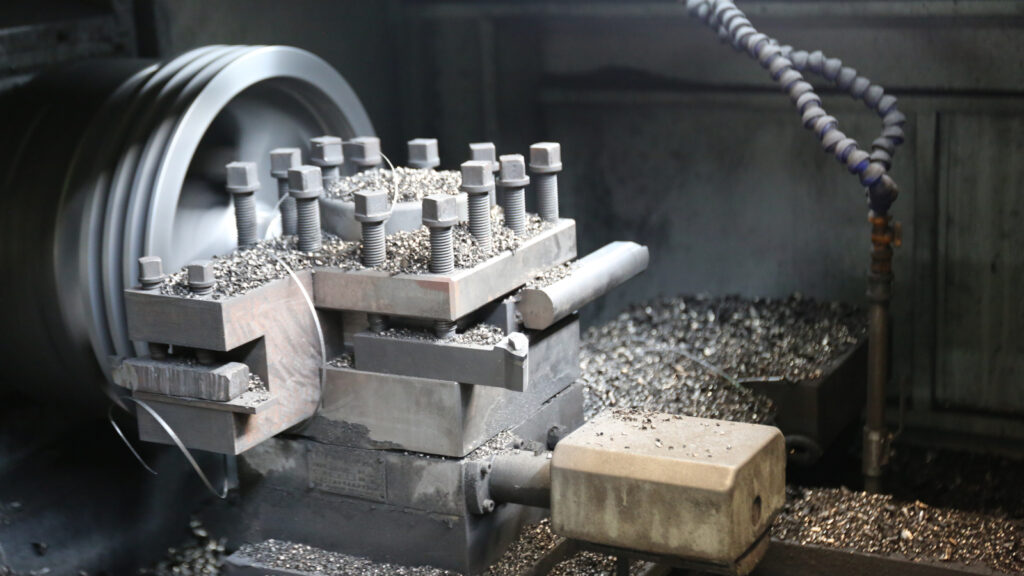

- Finishing: Parts are cut from the sprue, cleaned, and optionally machined or polished.

Why Manufacturers Choose Investment Casting?

Investment casting is highly regarded for its ability to produce parts with complex shapes and tight dimensional tolerances. It allows engineers to design without the limitations of traditional machining or forging. Since the ceramic mold captures fine detail from the wax model, the resulting castings typically have a smooth surface finish, reducing or eliminating the need for secondary processing.

One of the key strengths of investment casting is its material flexibility. It accommodates a wide variety of metals, including stainless steel, carbon steel, aluminum alloys, bronze, and specialty alloys. This makes it suitable for components that must withstand high temperatures, corrosion, or mechanical stress.

Although the tooling cost for wax molds can be higher than in sand casting, the long-term benefits—like reduced machining, improved performance, and lower scrap rates—often offset the initial expense, especially for medium to high production volumes.

Where Investment Casting Is Used

Because of its versatility and precision, investment casting is used in a wide range of industries. In aerospace, it is commonly used to produce turbine blades, brackets, and structural components where weight and precision are critical. In the automotive sector, the process is used for manifolds, turbocharger parts, and suspension components. It is also widely used in industrial machinery for pump bodies, valve housings, and impellers.

In the medical field, investment casting is ideal for manufacturing surgical tools and orthopedic implants that must meet strict dimensional and material requirements. Even the defense and firearms industries rely on this process for intricate weapon components and sight systems.

How It Compares to Other Casting Methods

Compared to sand casting, investment casting offers superior accuracy and surface quality, though it may not be as cost-effective for very large parts or extremely high volumes. Unlike die casting, it can be used for ferrous metals and parts that don’t require extremely high production runs. In many ways, it bridges the gap between flexibility and performance, offering the best of both worlds for complex, high-value components.

Our Investment Casting Capabilities

We offer complete investment casting services—from wax pattern creation to finishing and inspection. Our foundry supports a wide range of materials and can handle both prototype and volume production. With over 20 years of experience, we provide solutions tailored to meet strict industry standards, including support for OEM and custom designs.

Our in-house machining capabilities and quality control systems ensure that every part meets your specifications—on time and within budget.

We’ve spent decades building parts — and even longer building trust. Thousands of projects. Decades of know-how. Tons of capacity. We don’t just make metal parts — we make things work, and we’ve been doing it for over 25 years.