Cast to Last

Poured & Proven

Backed by 20+ years of experience, we provide reliable metal casting & machining services for customers worldwide.

Clients trust EATHU

Capacity (MT) per year

Tolerances as tight as

OEM Casting Services Tailored to Your Specs

Our casting service provides reliable, high-quality metal components tailored to your drawings and performance requirements. With extensive experience in both ferrous and non-ferrous casting, we support a wide range of applications across automotive, construction, agricultural machinery, and industrial equipment. From material selection to mold design and process control, every step is managed to ensure consistent quality, dimensional accuracy, and stable mechanical properties.

By combining in-house casting capabilities with machining support, we offer a streamlined solution that reduces lead time and production cost. Our team focuses on clear technical communication, strict quality inspection, and flexible production volumes, making it easy to move from prototype to series production. Whether you need complex geometries or cost-effective mass production, our casting service is built to deliver dependable results for long-term cooperation.

Engeering

Assistance

Cost

Optmization

Material

Selection

ISO

Compliant

Casting-CNC

Integration

Tolerance Standard

up to CT3

Full Range of Metals

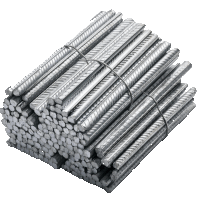

We offer OEM casting services with a full range of materials, including aluminum, stainless steel, iron, zinc, and alloys. This variety allows us to meet the specific strength, durability, and performance requirements of your project—whether for prototypes or mass production.

Iron

Stainless Steel

Carbon Steel

Aluminum

Zinc

Bronze

Magnesium

More...

EATHU’s strengths lie in our industry experience, advanced technology, integrated services, and commitment to quality and timely delivery. We provide flexible solutions that meet diverse customer needs with precision and reliability.

CAPABILITIES

We utilize a variety of casting techniques, including sand casting, die casting, investment casting, to meet diverse customer needs. Our expertise allows us to handle complex geometries and tight tolerances with consistent quality. We work with a wide range of materials, such as stainless steel, aluminum, and brass, chosen for their strength, durability, and excellent casting performance.

Our ability to integrate casting and CNC machining under one roof gives us a unique advantage in both cost effectiveness and efficiency. We take raw castings and finish them to tight tolerances, ensuring dimensional accuracy and surface quality. This streamlined process reduces handling, shortens lead times, and lowers overall production costs—ideal for OEMs seeking a complete manufacturing solution.

EQUIPMENT & QUALITY CONTROL

EATHU operates modern manufacturing facilities equipped with advanced casting and CNC machining equipment to ensure precision and efficiency at every stage of production. Our workshops support a full range of processes—from mold making and casting to machining, surface treatment, and final inspection.

Our QA/QC processes are designed to ensure that every part we deliver fully meets your engineering specifications. From material inspection to in-process checks, we maintain complete traceability and consistency throughout production.

RELIABLE. SCALABLE

Located in China’s manufacturing hub, we benefit from a vast network of reliable suppliers and abundant raw materials. This strong supply chain allows us to respond quickly to orders, reduce lead times, and maintain stable production—no matter the project scale.

From rapid prototyping and small-batch runs to large-scale manufacturing exceeding 100,000 parts, we accommodate projects of all sizes with exceptional precision and efficiency. Our flexible processes and advanced equipment ensure fast turnaround times without compromising quality.

- Solutions

Start Your

Project Today!

Ready to get started? Tell us about your casting project and we’ll take care of the rest — from engineering to final delivery.