Turning is one of the most fundamental and widely used machining processes in manufacturing. From automotive parts to aerospace components, this versatile technique plays a crucial role in shaping metals and other materials into precise, functional products. In this guide, we will cover everything you need to know about turning — from its definition and process to its applications, benefits, and modern advancements.

What Is Turning?

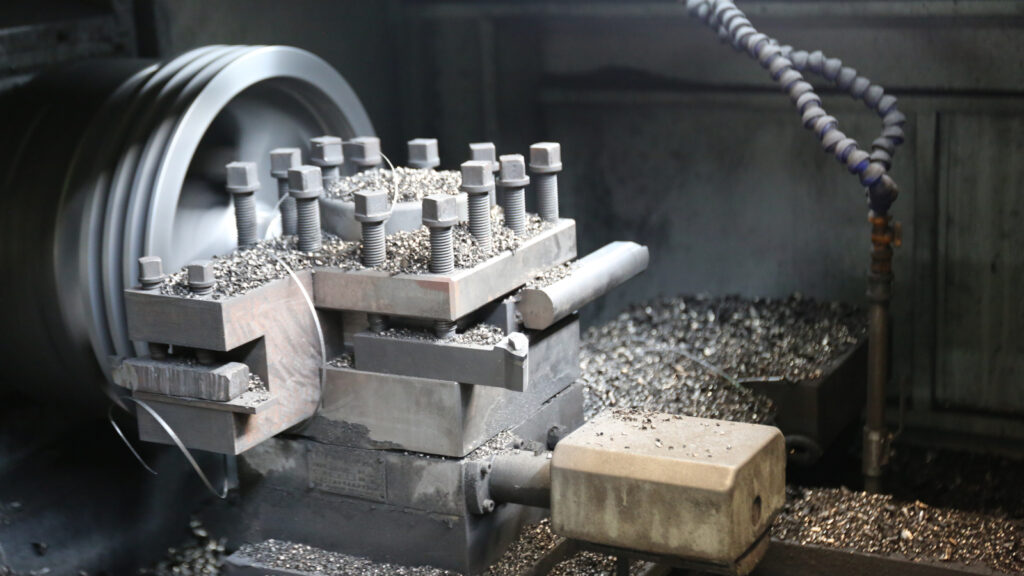

Turning is a machining process in which a cutting tool removes material from a rotating workpiece to create a cylindrical shape. This is typically performed on a lathe machine, which holds and spins the workpiece while the cutting tool moves linearly to trim away excess material.

The process can produce both simple shapes, like straight shafts, and complex geometries, such as tapered surfaces, threads, and grooves.

How the Turning Process Works

The process begins with securely mounting the workpiece, often in bar or rod form, in the lathe chuck. A cutting tool is then positioned according to the desired path and depth. As the lathe rotates the workpiece at a calculated speed (measured in revolutions per minute), the cutting tool advances into the material, removing it layer by layer. Several passes may be made, with roughing cuts to remove large amounts of material followed by finishing cuts to achieve the final dimensions and surface quality.

Main Types of Turning Operations

While the principle of turning is straightforward, there are variations to suit different shapes and requirements. Straight turning produces uniform diameters along the workpiece length, while taper turning creates conical shapes. Facing involves cutting a flat surface at the end of the workpiece, and parting removes a finished section from the raw material. Other operations include thread cutting for screw-like patterns and grooving for narrow slots. These techniques can be combined in a single setup to create complex components efficiently.

Advantages of Turning

Manufacturers rely on turning for its precision, versatility, and speed. CNC turning can achieve extremely tight tolerances, making it ideal for critical applications. The process also delivers excellent surface finishes, reducing or eliminating the need for secondary polishing. Because it works well with different materials and can produce both prototypes and mass-produced parts, turning remains a go-to method for industries seeking accuracy and efficiency.

Materials Used in Turning

Turning is compatible with a wide range of materials. Metals like steel, stainless steel, aluminum, brass, and titanium are common choices in engineering applications. Plastics such as nylon, acrylic, and PEEK are also machinable, along with certain composites like carbon fiber-reinforced polymers. The choice of material depends on the application’s performance requirements, durability needs, and budget considerations.

Applications of Turning

Turning is compatible with a wide range of materials. Metals like steel, stainless steel, aluminum, brass, and titanium are common choices in engineering applications. Plastics such as nylon, acrylic, and PEEK are also machinable, along with certain composites like carbon fiber-reinforced polymers. The choice of material depends on the application’s performance requirements, durability needs, and budget considerations.

Modern Advancements in Turning

Technological innovations have significantly improved the turning process. CNC automation minimizes human error and increases productivity, while multi-axis lathes allow for complex geometries to be completed in one setup. Cutting tool materials such as carbide, ceramics, and diamond coatings extend tool life and improve efficiency. In some facilities, real-time monitoring systems track cutting forces, temperatures, and vibrations to ensure consistent quality and prevent costly defects.