Investment Casting

Backed by 20+ years of experience, we provide reliable metal casting & machining services for customer worldwide.

Precision Investment Casting for Complex Metal Components

Investment casting, also known as lost wax casting or precision casting, is a manufacturing process that delivers highly detailed components with excellent surface finish straight from the mold. It allows for the creation of complex internal and external features, thin walls, and intricate internal channels—achieving near-net shape with minimal post-processing. Due to its precision and efficiency, investment casting is widely used in industries such as aerospace, defense, energy, and food processing.

We provide reliable OEM casting services tailored to your specs. From initial design and material selection to mold development and mass production, we deliver high-quality metal castings for a wide range of industries. Our team works closely with each customer to ensure precision, consistency, and on-time delivery.

Investment Casting Built for Precision

Our investment casting service delivers high-precision metal components with excellent surface finish and tight tolerances. Using advanced wax pattern technology and carefully controlled casting processes, we produce complex geometries that would be difficult or costly to achieve with other manufacturing methods. This makes investment casting an ideal solution for parts requiring intricate details, dimensional accuracy, and consistent quality.

Backed by decades of casting expertise and in-house CNC machining capabilities, we provide a fully integrated manufacturing solution from prototyping to production. We work closely with customers to optimize designs, select the right alloys, and ensure every component meets strict technical and performance requirements. The result is reliable, high-quality cast parts tailored to demanding industrial applications.

Investment casting is compatible with a wide range of metals, making it a versatile solution for many industries. Each alloy offers distinct advantages—stainless steel for corrosion resistance, carbon steel for strength, aluminum for lightweight parts, and bronze for wear resistance.

Material Options

Investment casting is a manufacturing process that delivers exceptional dimensional accuracy, fine surface finishes, and design flexibility. It is ideal for producing complex components with intricate geometries, reducing the need for secondary machining and material waste.

Key Advantages

Investment casting is widely used across industries that demand high precision, complex geometries, and reliable performance. Its ability to produce intricate shapes with tight tolerances makes it ideal for both functional and decorative components.

Application

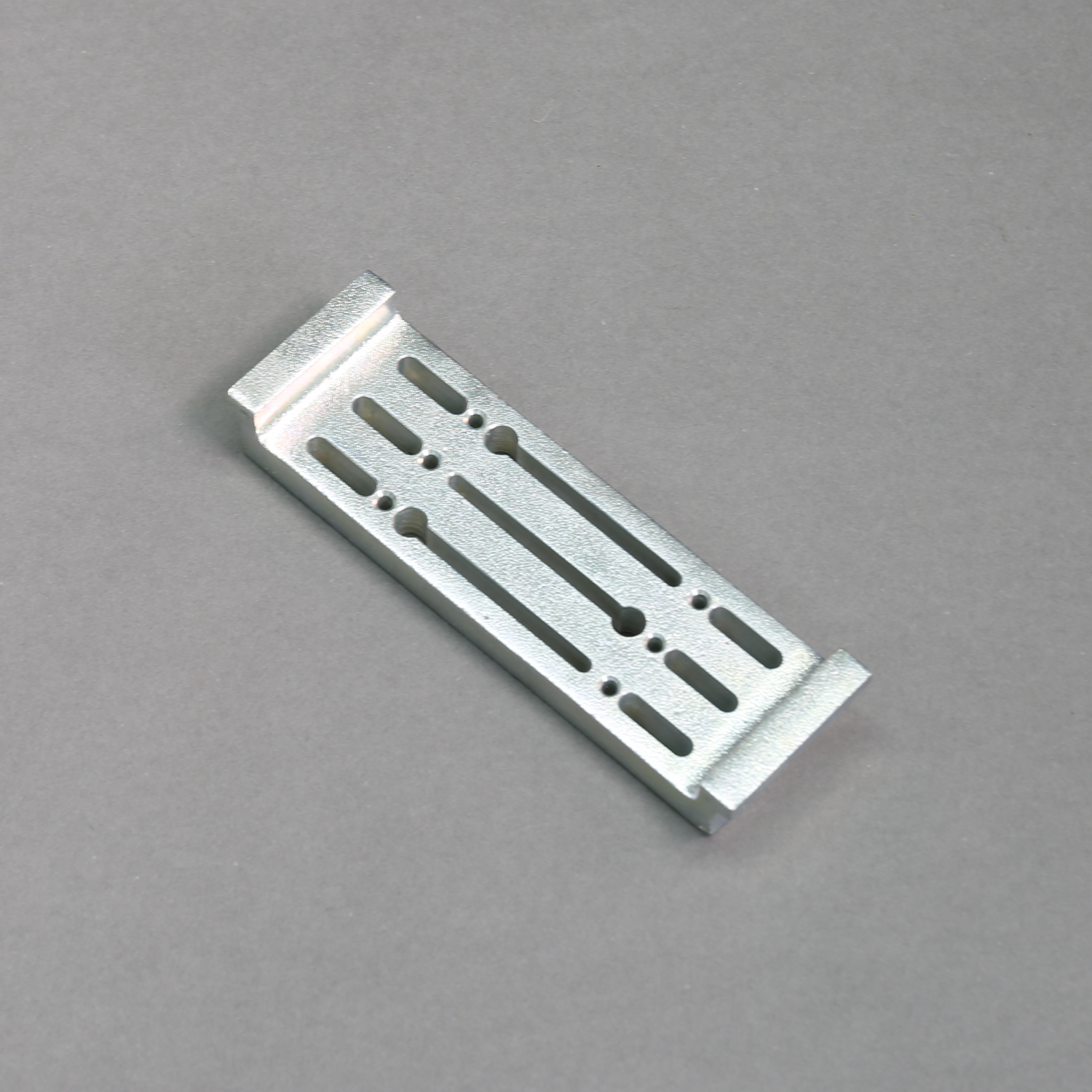

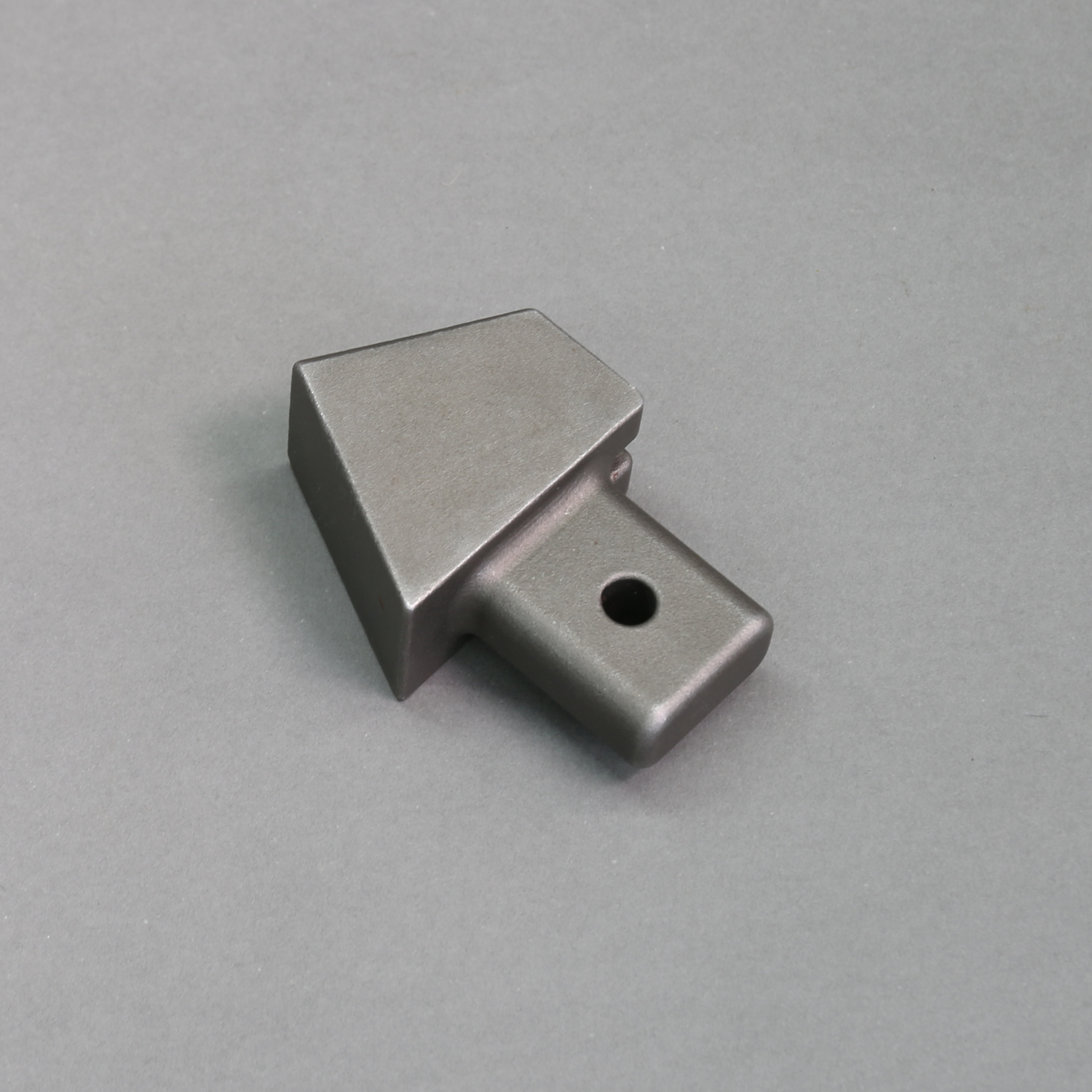

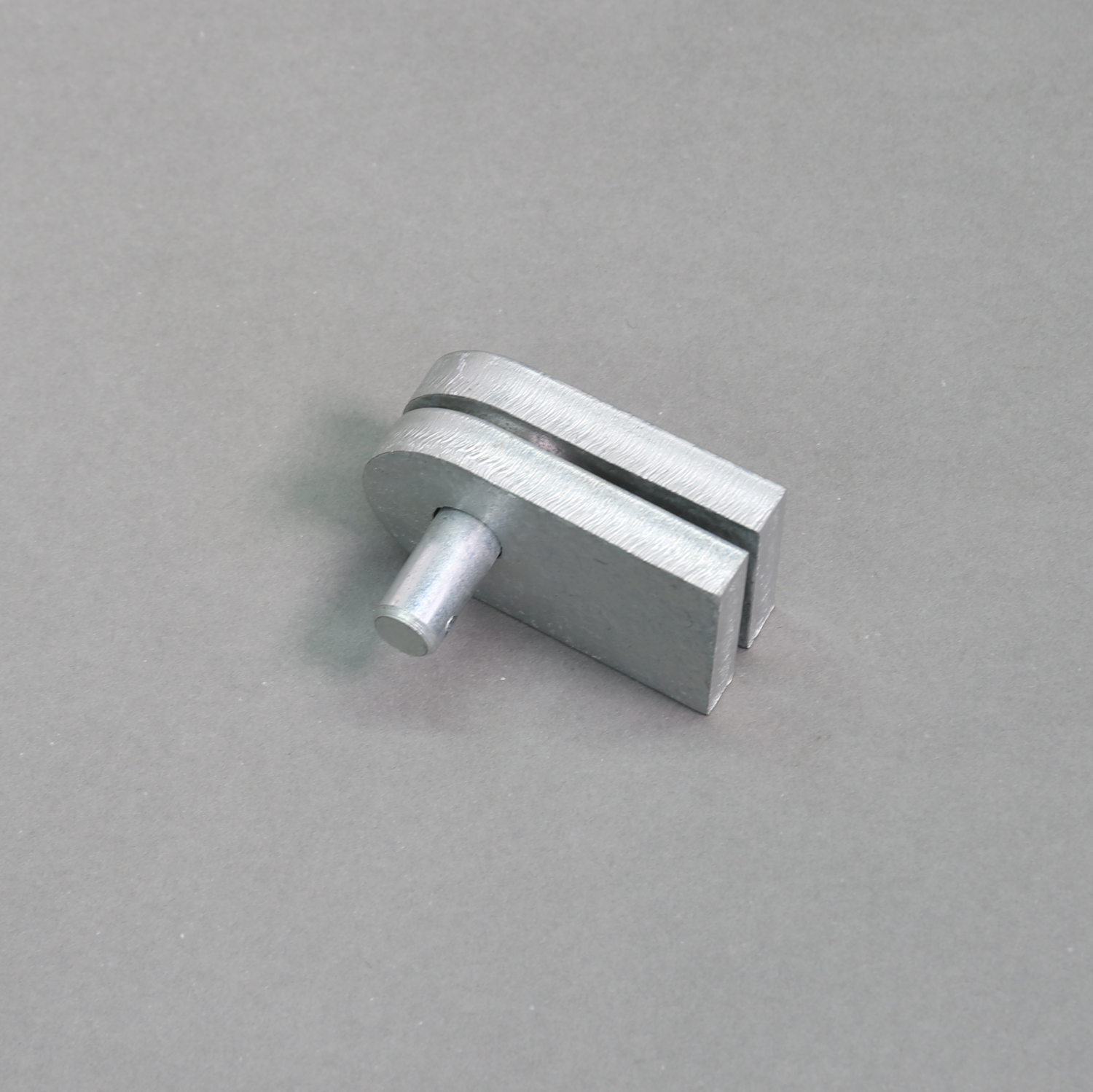

Castings in Focus

Join 1,200+ companies who have chosen EATHU for their casting projects.

- Instant Quote

- Engineering Support

- Factory Tour