Sand Casting

Backed by 20+ years of experience, we provide reliable metal casting & machining services for customer worldwide.

Reliable OEM Casting Services Tailored to Your Specs.

Sand casting is a flexible and cost-efficient method for producing metal parts with complex shapes. Using sand molds, we cast aluminum, iron, and other metals for both small and large production runs. EATHU offers end-to-end sand casting solutions, including pattern making, machining, and surface finishing—delivering reliable, high-quality parts to meet your exact needs.

We provide reliable OEM casting services tailored to your specs. From initial design and material selection to mold development and mass production, we deliver high-quality metal castings for a wide range of industries. Our team works closely with each customer to ensure precision, consistency, and on-time delivery.

CASTING WITH US!

At EATHU, we offer comprehensive metal casting services tailored to your exact specifications. With over 20 years of experience, we specialize in producing high-quality aluminum, iron, and steel castings using sand casting, die casting, and investment casting techniques. From design and mold making to machining and surface finishing, we manage the entire process in-house to ensure consistent quality, precision, and on-time delivery. Whether you need small batches or high-volume production, our casting solutions are reliable, cost-effective, and built to perform.

Sand casting is compatible with a variety of metals, allowing for flexibility in both performance and cost. The choice of material depends on the application, mechanical properties, and environmental conditions. We offer guidance in selecting the best alloy for your needs.

Material Options

Sand casting remains one of the most widely used metal casting methods due to its flexibility, affordability, and ability to produce complex parts in a wide range of sizes. It’s especially effective for custom and low-to-medium volume production, offering design freedom and fast turnaround at a competitive cost.

Key Advantages

Sand casting is widely used across industries thanks to its ability to produce durable metal parts with complex shapes at a low cost. It’s ideal for both large and small components, making it suitable for a broad range of functional and structural applications.

Application

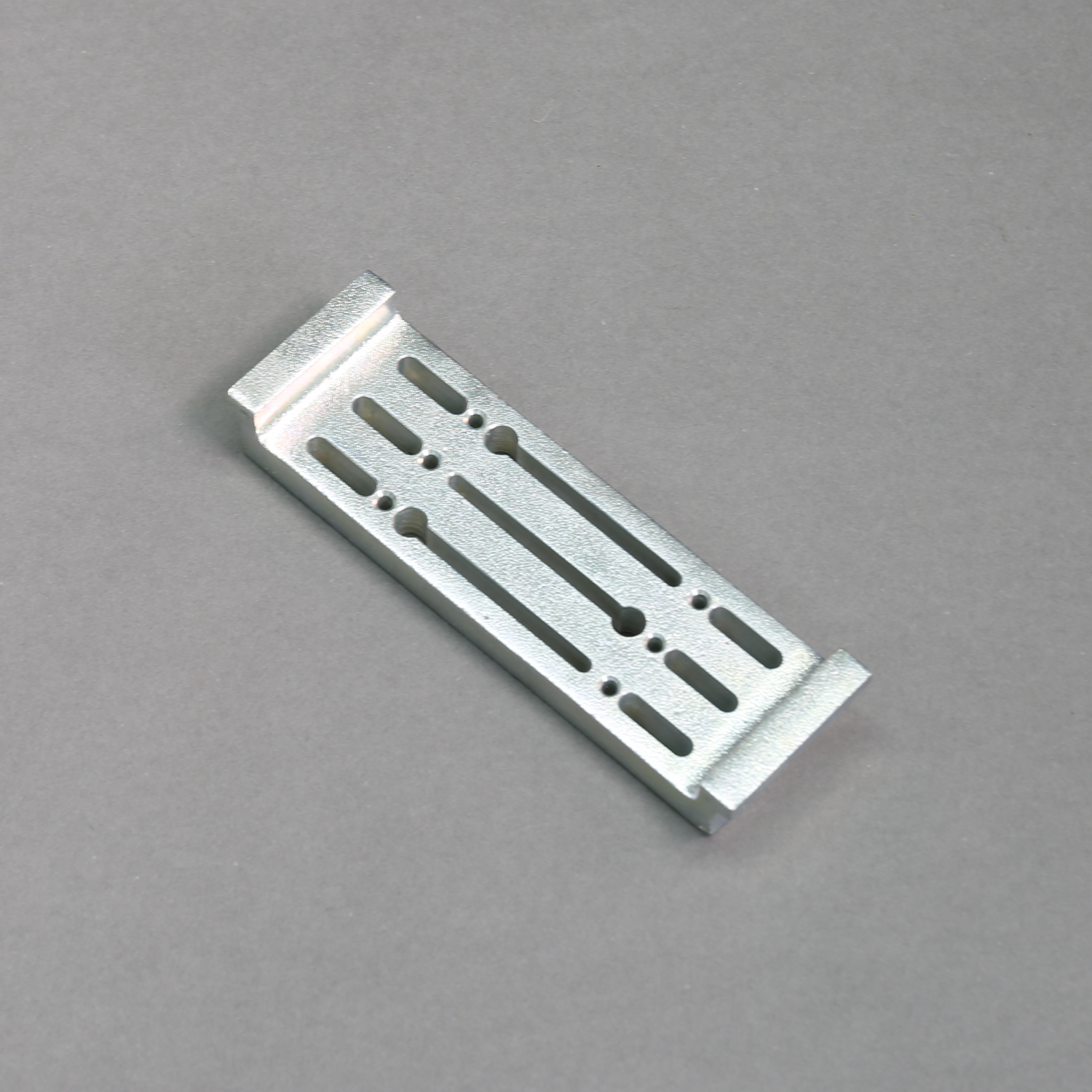

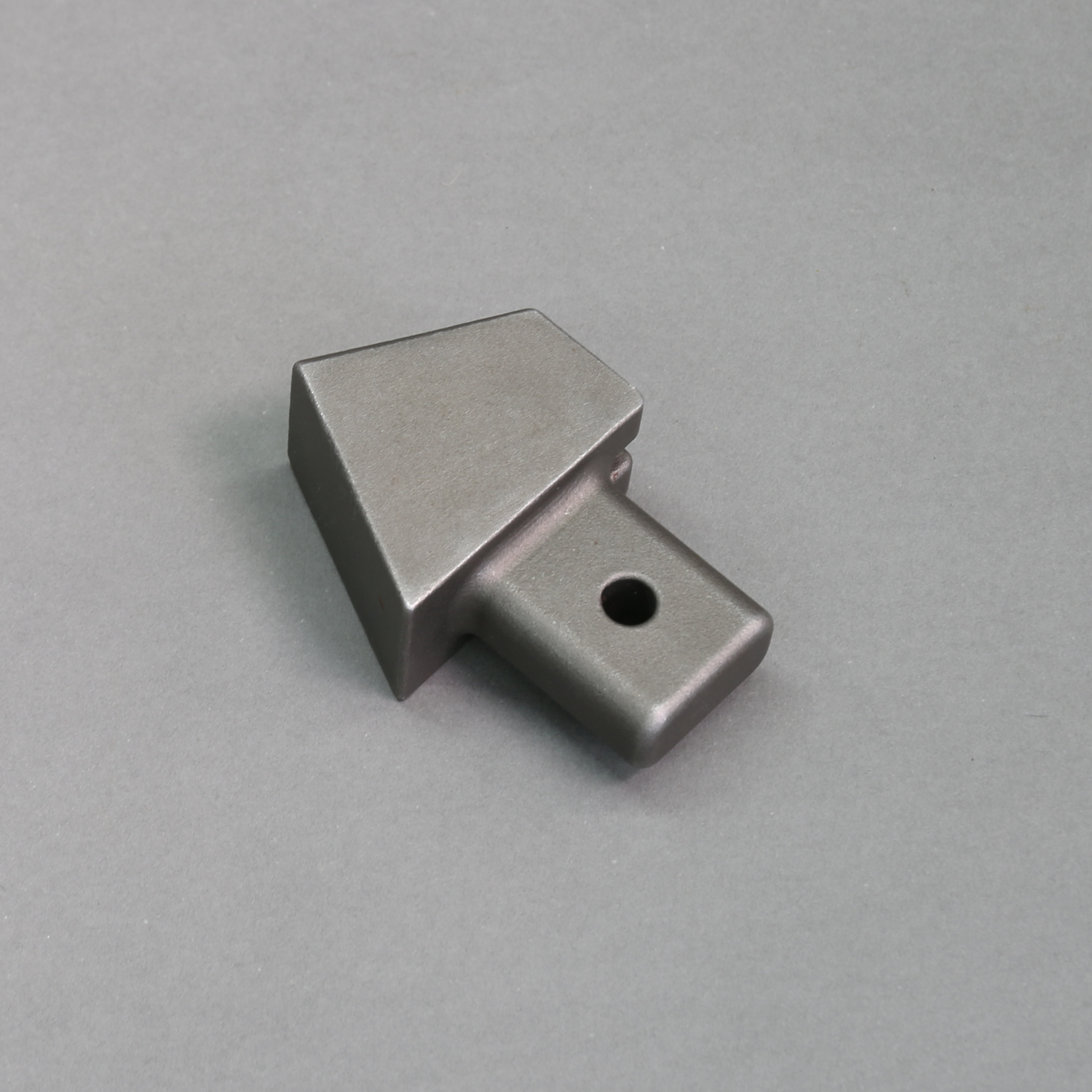

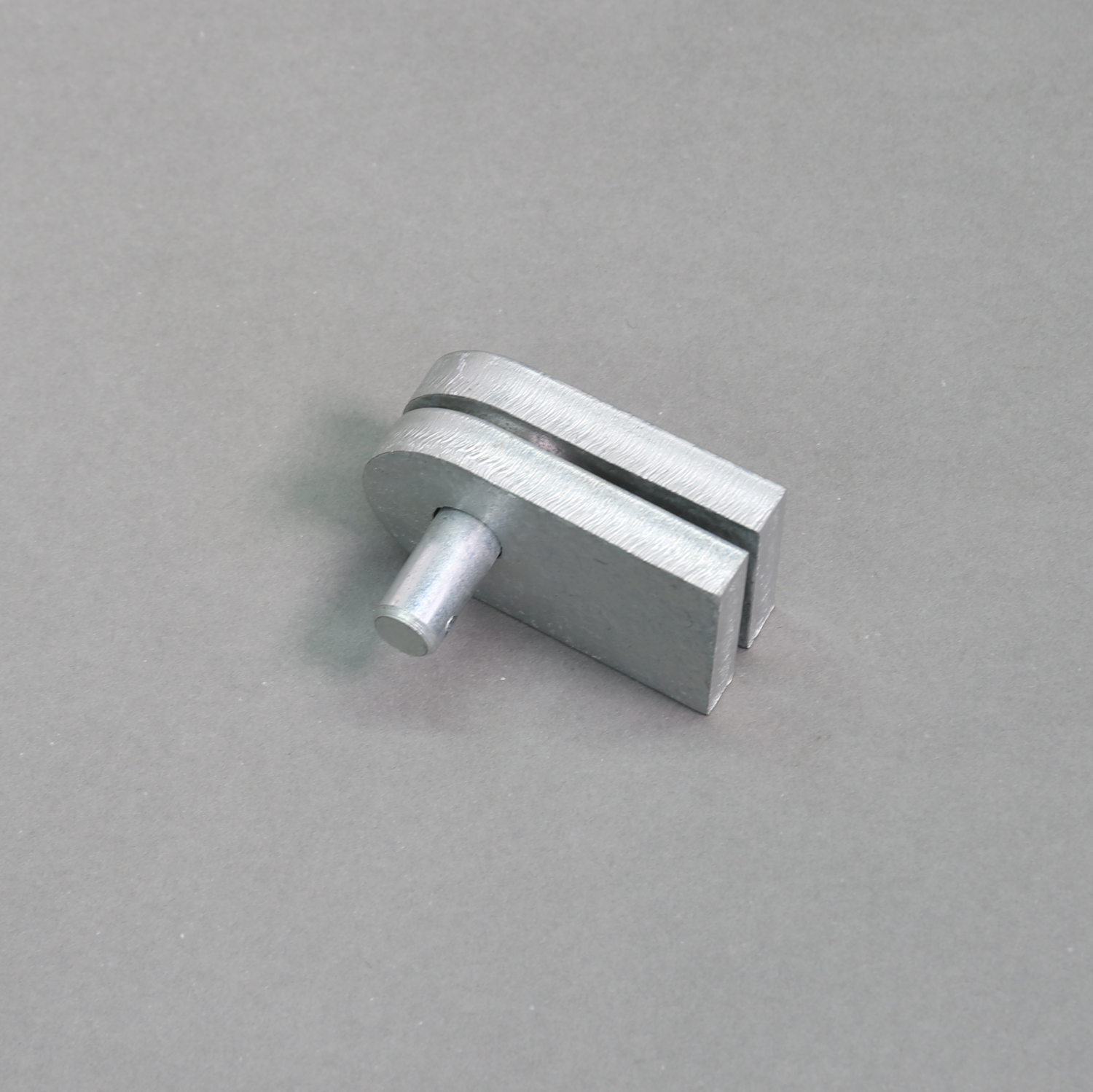

Castings in Focus

Join 1,200+ companies who have chosen EATHU for their casting projects.

- Instant Quote

- Engineering Support

- Factory Tour