In metal manufacturing, the choice of production method can determine not only the performance of the final component but also the cost, lead time, and overall success of a project. Among the many available processes, forging and casting stand out as two of the most widely used.

Both methods have been around for centuries, evolving alongside technology to meet the needs of industries ranging from aerospace to agriculture. But while they share the same goal—turning raw metal into a functional part—the way they achieve that goal is very different. Understanding these differences is essential for making the right decision for your application.

What Is Forging?

Forging is a process in which metal is shaped by compressive forces, often with the aid of hammers, presses, or dies. This shaping can be done at high temperatures (hot forging) or at or near room temperature (cold forging).

The key strength of forging lies in how it changes the metal’s internal structure. As the metal is deformed under pressure, its grain flow aligns to the shape of the part. This refined grain structure enhances mechanical properties such as tensile strength, impact resistance, and fatigue life. That’s why forged components are commonly found in aircraft landing gear, automotive crankshafts, mining tools, and other high-stress parts.

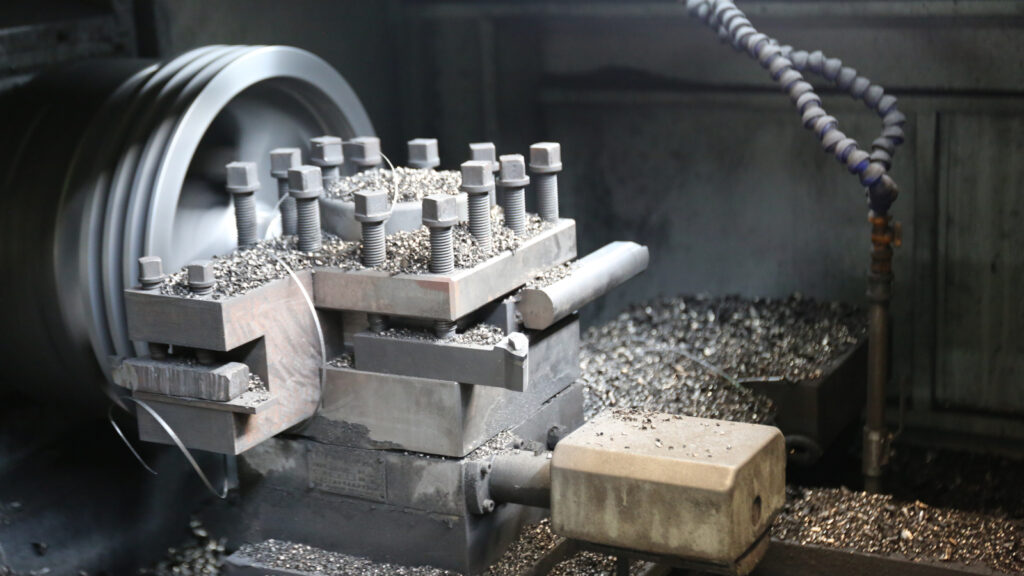

However, forging has its challenges. The process is typically best suited for simpler shapes, as producing intricate geometries can be difficult or even impossible. Tooling costs can also be high, making it less economical for small production runs. And in many cases, additional machining is needed to bring the forged part to its final dimensions and surface finish.

What Is Casting?

Casting takes a very different approach. Instead of shaping solid metal through force, it begins by melting the metal until it becomes liquid. This molten metal is then poured into a mold that defines the desired shape, allowed to cool and solidify, and finally removed from the mold.

The biggest advantage of casting is its design flexibility. Molds can be created to produce highly complex shapes, including hollow sections, thin walls, and intricate surface details—all in a single process. This makes casting ideal for pump housings, valve bodies, ornamental parts, and components with intricate internal channels.

Casting also allows the use of a broader range of materials, including alloys that would be too hard or brittle to forge. It can be cost-effective for both small and large production runs, especially when complexity is high. On the downside, cast parts generally don’t have the same strength and fatigue resistance as forged parts, and the process carries risks such as porosity, shrinkage, or inclusions if not carefully controlled.

Which to Choose?

To put it simply, if you were manufacturing a truck axle, aerospace landing gear, or oilfield drill bit, forging would likely be the better choice because of its unmatched strength and reliability. On the other hand, if you needed a complex valve body, turbine housing, or decorative aluminum component, casting would provide more design freedom and cost efficiency.

Some industries even use a combination of both methods—casting a near-net shape and then forging or machining it for critical features. This hybrid approach can optimize performance and cost.

Strength and Durability – Forging offers superior mechanical properties, making it the go-to choice for safety-critical and high-load applications.

Design Complexity – Casting allows for more intricate shapes, including features that cannot be achieved by forging.

Material Selection – If your project requires a specialty alloy, casting may offer more flexibility.

Production Volume – Forging is often more economical for medium to large batches, while casting can be cost-effective for any volume depending on complexity.

Lead Time and Tooling – Forging typically involves higher tooling costs and longer preparation, whereas casting molds can be quicker and less expensive to produce for small runs.

Conclusion

There’s no single winner in the forging vs casting debate. The “better” option depends entirely on your application requirements. Forging delivers unbeatable strength and durability, while casting shines in its ability to produce complex, detailed shapes at a competitive cost.

The best way to make the right choice is to consult with an experienced metal manufacturing partner who understands both processes. They can assess your design, performance requirements, and budget, then guide you toward the method that will deliver the best results.

Whether you need forged parts for heavy-duty machinery or precision-cast components for intricate assemblies, the key is selecting a process that aligns with your technical goals and economic constraints.