Sand casting is one of the most widely used metal casting processes in modern manufacturing. Known for its simplicity, versatility, and cost-efficiency, this traditional method plays a vital role in producing everything from engine components to industrial machinery parts.

In this article, we’ll explore the sand casting process in detail—how it works, its advantages and limitations, and why it remains a top choice for metal part production.

What Is Sand Casting?

Sand casting is a process where molten metal is poured into a mold made of compacted sand. The mold takes the shape of the part, and after the metal solidifies, the sand is broken away to reveal the casting.

This method is particularly useful for producing complex geometries and large components that may be difficult or costly to manufacture using other techniques.

How the Sand Casting Process Works

The sand casting process begins with pattern making, where a replica of the final part is created from wood, plastic, or metal. This pattern is used to form the cavity inside the mold. Next comes mold preparation, where the pattern is placed inside a molding box and packed with special sand mixed with a binder to hold its shape. Once the pattern is removed, it leaves a hollow cavity shaped like the part. If the casting requires hollow sections, sand cores are inserted into the mold to form internal features.

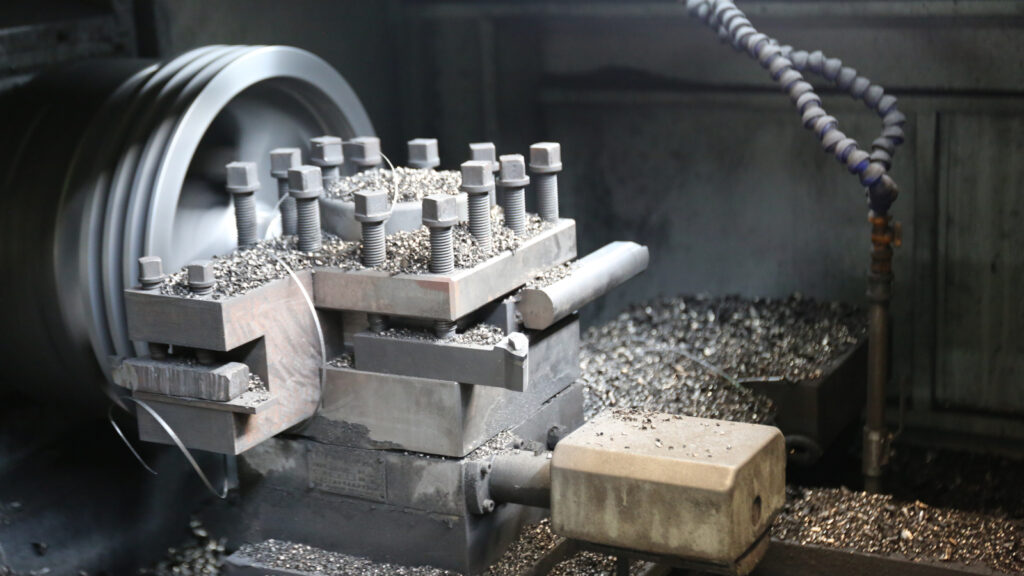

After the mold is ready, molten metal is carefully poured into the cavity through a gating system. The metal is then allowed to cool and solidify, taking on the shape of the mold. Once the casting has cooled, the mold is broken apart in a process known as shakeout, and the solid metal part is removed. The final stage involves cleaning and finishing the casting—removing excess material, leftover sand, and performing any necessary machining or heat treatment to meet final specifications.

Pros & Cons of Sand Casting

One of the biggest advantages of sand casting is its cost-effectiveness, especially for low-to-medium production runs. It also allows for great design flexibility, supporting complex shapes and large dimensions that are difficult to produce using other casting methods.

Sand casting molds are relatively easy and inexpensive to prepare, and the process can be adapted to different metal alloys without significant retooling.

Limitations of Sand Casting

One of the biggest advantages of sand casting is its cost-effectiveness, especially for low-to-medium production runs. It also allows for great design flexibility, supporting complex shapes and large dimensions that are difficult to produce using other casting methods.

Sand casting molds are relatively easy and inexpensive to prepare, and the process can be adapted to different metal alloys without significant retooling.

Applications of Sand Casting

Sand casting is used in a wide range of industries. In automotive manufacturing, it’s commonly used for engine blocks and transmission housings. The construction industry relies on it for producing heavy-duty parts such as brackets, covers, and supports. In agriculture, sand-cast components include housings, gears, and frame parts for machinery.

When to Choose Sand Casting

Sand casting is used in a wide range of industries. In automotive manufacturing, it’s commonly used for engine blocks and transmission housings. The construction industry relies on it for producing heavy-duty parts such as brackets, covers, and supports. In agriculture, sand-cast components include housings, gears, and frame parts for machinery.

Sand casting remains a reliable and economical choice for manufacturing a broad range of metal parts. With its adaptability to different materials, large part sizes, and intricate shapes, it continues to support industries worldwide with durable and high-performing components.