CNC Turning

Our CNC turning services produce precise, reliable parts, supporting a wide range of materials and tolerances for OEM requirements.

CNC Turning Services for Precision Machined Metal Parts

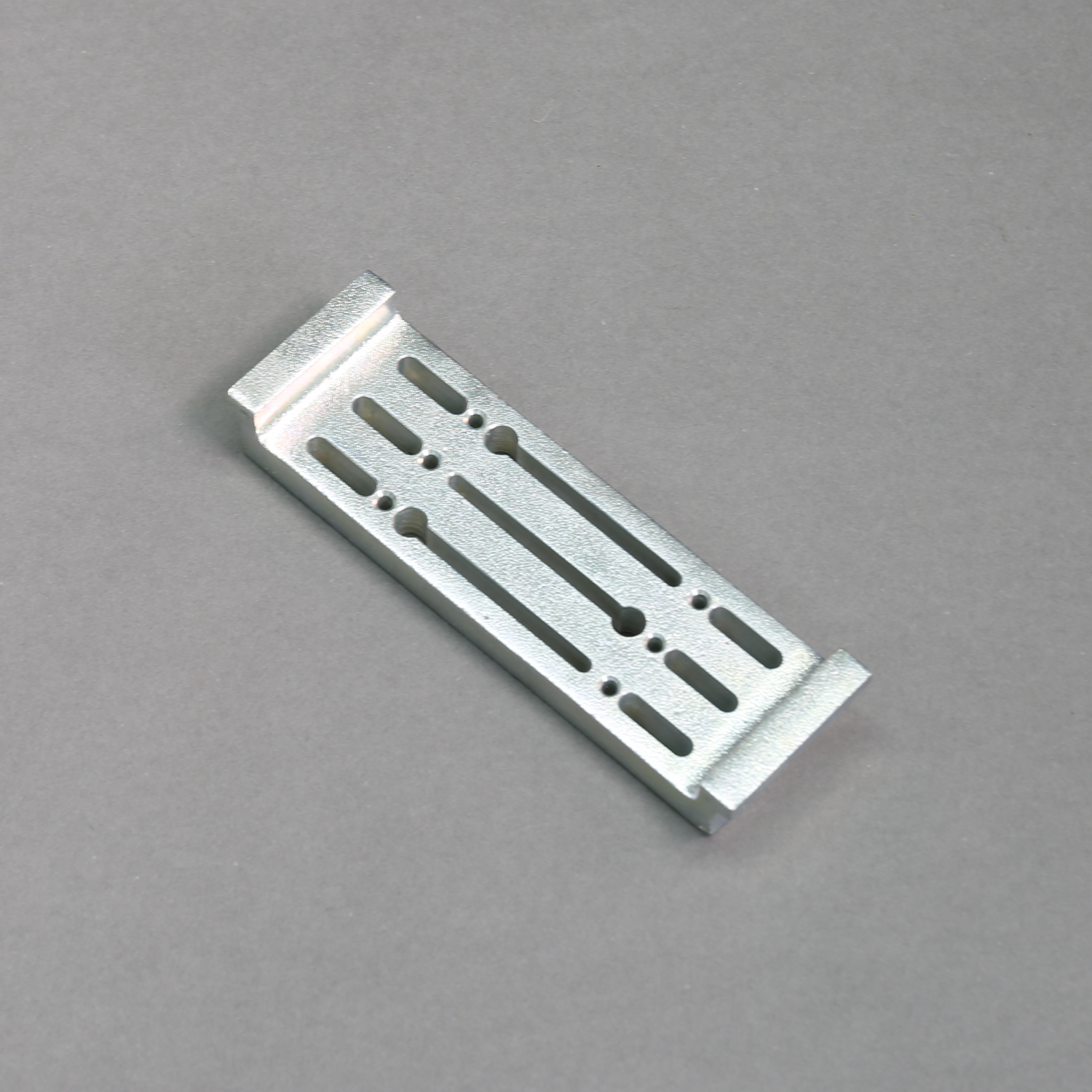

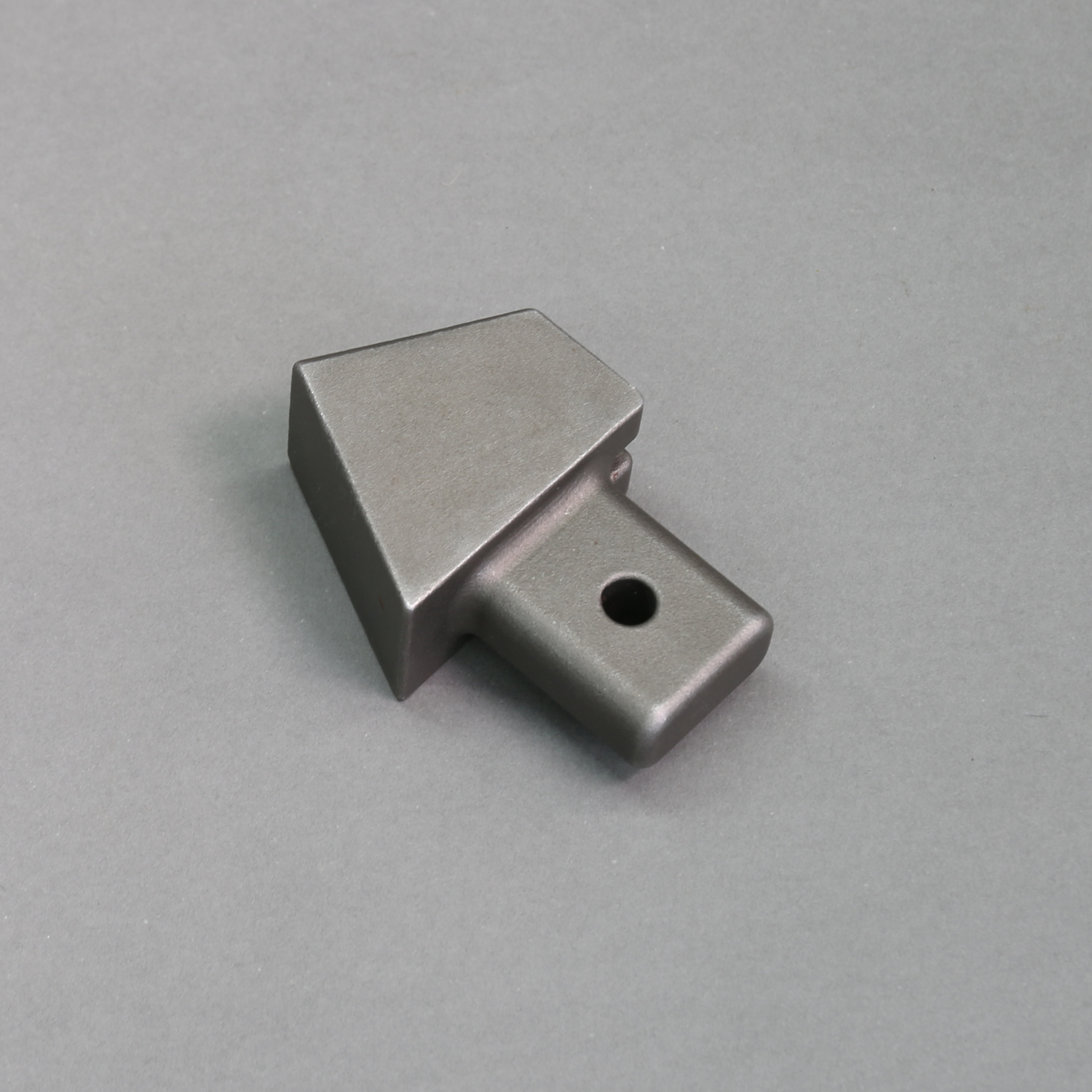

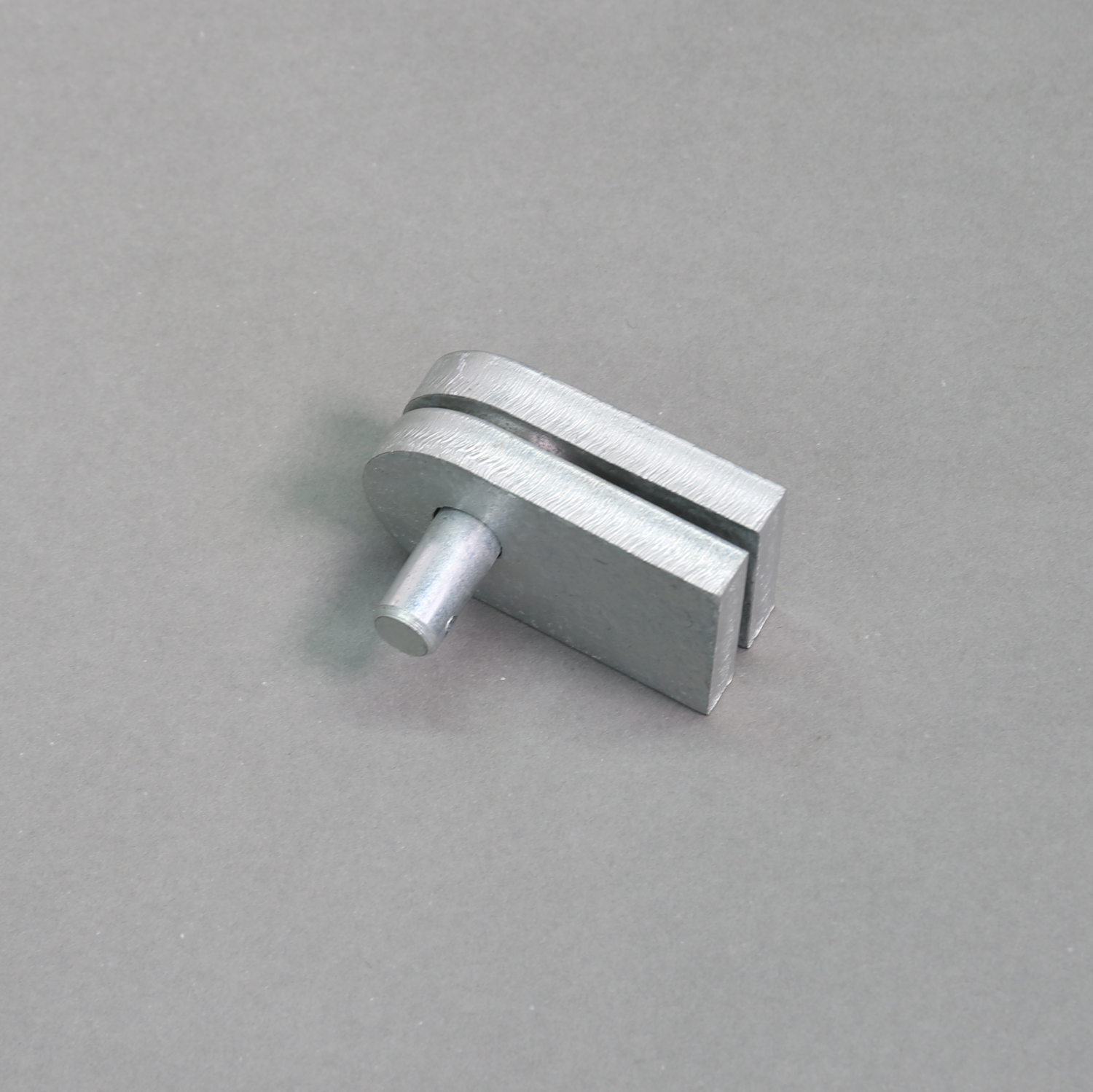

CNC turning is a machining process where a cutting tool removes material from a rotating workpiece to create precise cylindrical shapes. Controlled by computer programs, CNC lathes offer high accuracy and repeatability, making them ideal for producing shafts, bushings, fasteners, and other round or symmetrical parts. It’s a core method in modern manufacturing for achieving tight tolerances and smooth finishes.

Our CNC turning centre is equipped to handle high-precision machining for both small and large production runs. With advanced tooling and stable processes, it ensures excellent dimensional accuracy, smooth surface finishes, and consistent results across a wide range of materials. This capability allows us to efficiently produce complex turned components that meet strict OEM quality requirements.

Get Precision CNC Turning for Your Custom Parts

Our CNC turning services are designed to deliver precise, repeatable results for a wide range of cylindrical metal parts. Equipped with advanced CNC lathes and supported by experienced machinists, we manufacture shafts, bushings, pins, threaded parts, and other turned components with tight tolerances and excellent surface finishes.

We work with various metals and alloys and support everything from prototypes to stable production runs, ensuring consistent quality, efficient lead times, and reliable performance for demanding industrial applications.

CNC turning is compatible with a wide variety of metals and plastics, allowing for great flexibility and versability. The choice of material depends on the part’s strength, durability, corrosion resistance, and machinability requirements. We work with high-quality raw materials to ensure reliable and consistent performance in every turned part.

CNC Turning Materials

CNC turning offers high precision, consistent quality, and fast production for cylindrical parts. It reduces manual labor, minimizes errors, and can handle a wide range of materials, making it ideal for both small batches and large-scale manufacturing.

Advantages of CNC Turning

CNC turning is used to make precise cylindrical parts like shafts, bushings, and threaded components. It serves industries such as automotive, aerospace, and machinery, offering high accuracy, repeatability, and efficient production.

Applications of CNC Turning

Castings in Focus

Join 1,200+ companies who have chosen EATHU for their casting projects.

- Instant Quote

- Engineering Support

- Factory Tour