Metal casting is one of the oldest and most versatile manufacturing methods in human history. From ancient tools to modern-day industrial parts, casting has enabled the production of countless components with precision and efficiency. In this article, we’ll break down the key types of casting, how the process works, and where it’s used in today’s industries.

What is Metal Casting?

Metal casting is a manufacturing process where molten metal is poured into a mold, allowed to solidify, and then removed to form a finished part. It’s used to produce both simple and highly complex shapes that would be difficult or costly to machine from solid material. Casting supports a broad range of metals and is suitable for both custom components and high-volume industrial production.

How Metal Casting Works

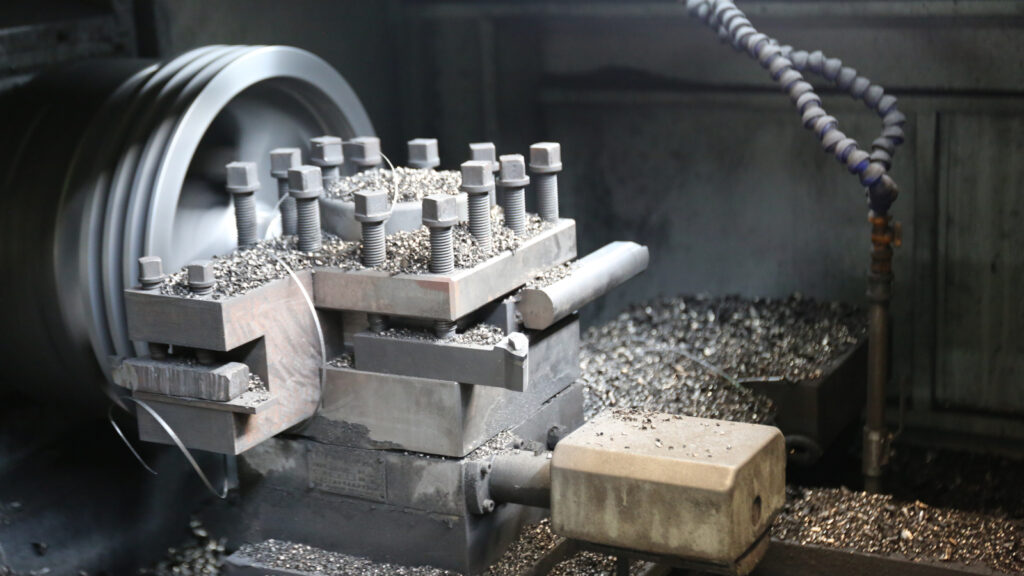

Metal casting works by melting metal into a liquid state and pouring it into a mold that has the shape of the desired part. The mold is usually made from sand, ceramic, or metal, depending on the casting method. Once the molten metal fills the cavity, it is left to cool and solidify. After cooling, the mold is removed to reveal the solid metal casting. The part may then go through cleaning, trimming, or machining to achieve the required dimensions and surface finish. This process allows manufacturers to produce complex metal components with high strength and accuracy, often at a lower cost compared to other manufacturing methods.

Metal Casting Processes

There are many casting processes that are applied in the metal casting industry. Each casting process has its advantages, depending on the material used, part complexity, and production volume.

Sand Casting. A widely used process ideal for large and heavy components, sand casting involves forming a mold from sand around a pattern, then pouring molten metal into the cavity.

Investment Casting. Also called lost-wax casting, this method is used for producing highly detailed, precise parts using ceramic molds formed around wax patterns.

Die Casting. Die casting uses steel molds and high pressure to inject molten metal, resulting in parts with excellent surface finish and tight tolerances.

Lost Foam Casting. In this method, foam patterns are used instead of wax. The foam vaporizes when the molten metal is poured, creating complex parts without cores.

Permanent Mold Casting. This method involves reusable molds made of metal, providing better consistency and mechanical properties than sand molds.

Types of Metals Used in Casting

Casting can be performed with a wide range of metals, each offering distinct properties for specific applications.

Aluinum. Lightweight and corrosion-resistant, aluminum is commonly used in automotive, aerospace, and consumer product manufacturing.

Iron. Cast iron and ductile iron are strong, wear-resistant, and widely used in construction, heavy machinery, and piping.

Steel. Steel castings are known for their high strength and are used in demanding environments like mining, transportation, and infrastructure.

Cooper Alloys. These alloys offer excellent corrosion resistance and are often used in plumbing, electrical, and marine applications.

- Others. Materials like magnesium, zinc, and nickel-based alloys, are also used for specialized applications that require unique combinations of performance and manufacturability.

Applications of Metal Casting

Metal casting is essential in many industries due to its versatility and cost-efficiency.

Automotive. Engine blocks, gearboxes, wheels, and brake components are often cast to meet performance and durability standards.

Construction & Infrastructure. Casting is used for manhole covers, structural supports, brackets, pipe fittings, and architectural details.

Agriculture & Heavy Equipment. Tractors, harvesters, and construction machines rely on cast parts like housings, arms, and counterweights.

Aerespace. Precision casting enables the production of lightweight, complex parts used in turbines, structural components, and aerospace systems.

Manufacturing and Industrial Equipment. Casting supports the production of machinery frames, motor housings, pumps, valves, and custom industrial tools.

Why Choose Metal Casting?

Metal casting remains a go-to manufacturing solution due to its ability to create complex shapes with minimal material waste. It provides excellent design flexibility and is compatible with nearly all metal types. Casting is also scalable—supporting everything from one-off prototypes to large-volume production with consistent quality.

From the creation of a pattern to the final product, metal casting is a precise and efficient way to produce high-quality metal components for a wide range of industries. With multiple casting processes and material options available, it offers unmatched versatility for manufacturers worldwide.

If you’re looking for dependable casting solutions backed by decades of experience and modern foundry technology, get in touch with our team today. We’ll help you choose the right process and material for your next project.

We’ve spent decades building parts — and even longer building trust. Thousands of projects. Decades of know-how. Tons of capacity. We don’t just make metal parts — we make things work, and we’ve been doing it for over 25 years.