Steel castings and iron castings are two of the most widely used materials in manufacturing, powering industries from construction and automotive to heavy machinery and mining. While they may appear similar in form, their composition, performance, and cost vary significantly. Understanding these differences is essential for selecting the right material for your project.

Understanding Steel Castings

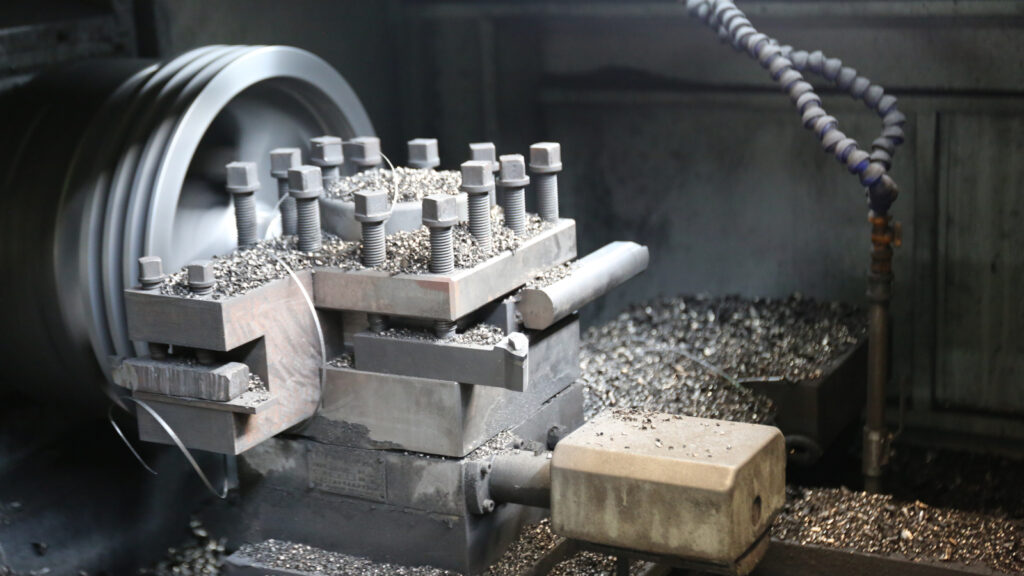

Steel castings are produced by pouring molten steel into molds, where the metal solidifies into precise shapes. Steel is primarily an alloy of iron and carbon, but it contains less carbon than cast iron—typically under 2%. This lower carbon content gives steel greater toughness and ductility. Manufacturers often add alloying elements like manganese, chromium, or nickel to enhance specific properties, such as strength, corrosion resistance, or wear resistance. Because of their ability to withstand high stress and impact, steel castings are a preferred choice for demanding applications like mining machinery, marine components, and structural parts.

Understanding Iron Castings

Iron castings are created by pouring molten iron into molds. With a carbon content ranging from 2% to 4%, cast iron is harder and more wear-resistant than steel but also more brittle. The high carbon content forms graphite structures within the metal, which improve machinability and provide natural vibration damping. Different types of cast iron—such as gray iron, ductile iron, and white iron—offer unique combinations of strength, wear resistance, and flexibility, making them suitable for applications like engine blocks, pump housings, and heavy-duty machine bases.

Strength, Wear Resistance, and Cost Differences

In terms of strength and toughness, steel castings generally outperform iron castings. Steel can handle higher tensile loads and is less prone to fracture under impact, making it ideal for pressure vessels, cranes, and high-load-bearing parts. Cast iron, while not as strong in tension, excels in compression and offers exceptional wear resistance, especially in abrasive environments.

Corrosion performance can also differ. Untreated steel is more prone to rust, but alloying with elements like chromium can significantly improve its resistance. Cast iron resists certain forms of corrosion naturally, though ductile iron provides better all-around performance in moist or chemical-rich environments.

From a cost perspective, iron castings are typically cheaper to produce. They require lower melting temperatures and simpler processing, which translates into energy and labor savings. Steel castings, due to their higher production costs and alloying requirements, are generally more expensive.

Making the Right Choice

If your application demands high strength, impact resistance, and long-term durability, steel castings are the safer choice. They are well-suited to heavy-duty, safety-critical environments. If your priority is wear resistance, vibration damping, and cost efficiency, iron castings may be the better fit, especially for parts that won’t face severe impact loads.

The decision between steel and iron ultimately comes down to the operating environment, mechanical requirements, and budget considerations. By matching the material’s strengths to your project’s needs, you can ensure both performance and cost-effectiveness.