Your Specs

Our Standard

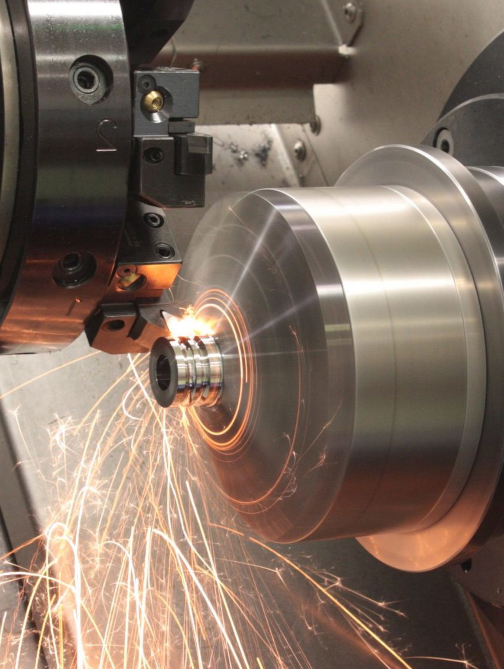

At EATHU, casting and CNC machining work as one. We leverage advanced CNC technology to deliver metal parts that meet exact specs.

Machinery axis

Surface roughness

Tolerances as tight as

Precision CNC Machining Services for Custom Metal Parts

CNC machining offers unmatched precision, repeatability, and efficiency in manufacturing. It allows for complex designs to be produced with tight tolerances and minimal human error. With fast setup and automation, CNC machining reduces production time and costs, making it ideal for both prototyping and large-scale production.

At EATHU, we provide a wide range of CNC machining services, including 3- to 5-axis milling, precision CNC turning, simultaneous 5-axis machining, Swiss-type turning, and CNC grinding. Whether it’s complex geometries or tight-fitting components, we ensure every part meets your exact specs.

Consistency &

Repeatability

Tight

Tolerances

Design

Flexibility

Efficiency

& Speed

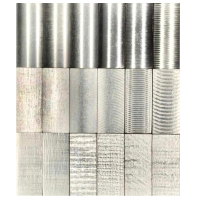

Surface Finishes

We offer a comprehensive selection of surface finishes to meet your exact specifications and enhance both the appearance and durability of your parts. Options include anodizing, powder coating, polishing, plating, sandblasting, and more.

As Machined

Brushing

Bead Blasting

Anodizing

Polishing

Silkscreen

Laser Marking

More...

EATHU’s strengths lie in our industry experience, advanced technology, integrated services, and commitment to quality and timely delivery. We provide flexible solutions that meet diverse customer needs with precision and reliability.

CAPABILITIES

We utilize a variety of casting techniques, including sand casting, die casting, investment casting, to meet diverse customer needs. Our expertise allows us to handle complex geometries and tight tolerances with consistent quality. We work with a wide range of materials, such as stainless steel, aluminum, and brass, chosen for their strength, durability, and excellent casting performance.

Our ability to integrate casting and CNC machining under one roof gives us a unique advantage in both cost effectiveness and efficiency. We take raw castings and finish them to tight tolerances, ensuring dimensional accuracy and surface quality. This streamlined process reduces handling, shortens lead times, and lowers overall production costs—ideal for OEMs seeking a complete manufacturing solution.

EQUIPMENT & QUALITY CONTROL

EATHU operates modern manufacturing facilities equipped with advanced casting and CNC machining equipment to ensure precision and efficiency at every stage of production. Our workshops support a full range of processes—from mold making and casting to machining, surface treatment, and final inspection.

Our QA/QC processes are designed to ensure that every part we deliver fully meets your engineering specifications. From material inspection to in-process checks, we maintain complete traceability and consistency throughout production.

RELIABLE. SCALABLE

Located in China’s manufacturing hub, we benefit from a vast network of reliable suppliers and abundant raw materials. This strong supply chain allows us to respond quickly to orders, reduce lead times, and maintain stable production—no matter the project scale.

From rapid prototyping and small-batch runs to large-scale manufacturing exceeding 100,000 parts, we accommodate projects of all sizes with exceptional precision and efficiency. Our flexible processes and advanced equipment ensure fast turnaround times without compromising quality.

- Solutions

Start Your Project Today!

Ready to get started? Tell us about your casting project and we’ll take care of the rest — from engineering to final shipping.